- Home Page

- Company Profile

-

Our Products

- Power Chuck And Chuck Spares

- Industrial Gears

- GNMT Precision Vices

- Lathe Machine

- Lead Screws

- Revolving Center

- CNC Lathe Turret Boring Sleeve

- Drill Machines

- Rotary Cylinders

- Universal Dividing Heads

- Angle Plates

- Sliding Tables

- Rotary Table

- Boring Head Set

- Industrial Grinder

- Milling Machine

- Operating Handles

- Back Plates / Mounting Flanges

- Tapping Machine

- Surface Grinding Machine

- Band Saw Machine

- Face Plate Jaws

- Milling Reduction Sockets

- Jaws Boring Rings

- Bonet Bonmac Independent Dog Chuck

- Magnet Chuck

- Drill Chuck

- KKF Independent Dog Chuck

- Seco Independent Dog Chuck

- Soft Jaws CNC Chucks

- Deluxe Independent Dog Chuck

- Hard Jaws CNC Chucks

- Collet Power Chucks

- True Chuck

- ACCURACY ADJUSTABLE CHUCK

- CHUCK Spare Parts

- COOKER LATHE CHUCKS

- ACCURACY ADJUSTABLE CHUCK

- SECO TRUE CHUCK

- TURNO TRUE CHUCK

- DUST PROOF SELF CENTRING CHUCK

- MTM TRUE CHUCK

- PNEUMATIC CHUCK

- DELUXE SELF CENTERING CHUCK

- GAMET SELF CENTERING CHUCK

- MIEKA TRUE CHUCK

- MASTER GRIPPING CHUCK

- MASTER GRIPPING CHUCK ( TURNO)

- Master Gripping Chuck ( Seco)

- ZITHER TRUE CHUCK

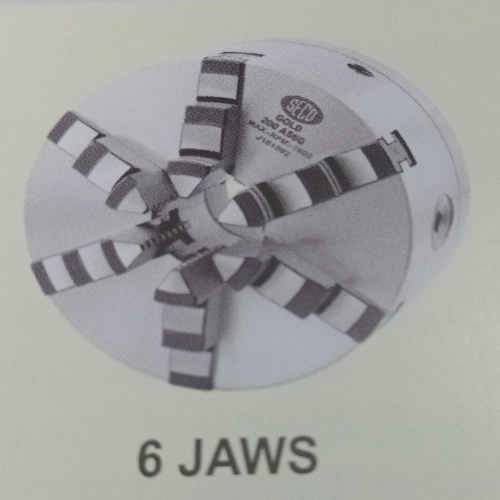

- Six Jaws True Chucks

- Collet Chuck

- Distributor

- Contact Us

ACCURACY ADJUSTABLE CHUCK

14500.00 INR/Piece

Product Details:

- Product Type Accuracy Adjustable Lathe Chuck

- General Use Precision workholding for CNC, VMC, Lathe & Grinding machines

- Material Stainless Steel

- Type Lathe Chuck

- Capacity 3 Ton

- Weight (kg) 20 Kilograms (kg)

- Computerized No

- Click to view more

X

ACCURACY ADJUSTABLE CHUCK Price And Quantity

- 14500.00 - 15000.00 INR/Piece

- 2 Piece

- 14500.00 INR/Piece

ACCURACY ADJUSTABLE CHUCK Product Specifications

- Manual

- Lathe Chuck

- No

- Accuracy Adjustable Lathe Chuck

- No

- 20 Kilograms (kg)

- 3 Ton

- 200 Millimeter (mm)

- Low Energy Consumption, Internal Cooling, High Quality

- Stainless Steel

- Standard Grey / Black Oxide

- 3 , 4 , 6

- Precision workholding for CNC, VMC, Lathe & Grinding machines

- No

- 1

ACCURACY ADJUSTABLE CHUCK Trade Information

- TKD

- 20 Piece Per Month

- 1 Week

- Contact us for information regarding our sample policy

- CORRUGATED CORASIS

- Middle East

- All India

- A 80MM to 315MM accuracy adjustable chuck, as a precision machine tool accessory, does not typically have individual product certifications like a CE mark. Its quality and performance are instead guaranteed by the manufacturer's quality management system and its adherence to strict design and performance standards. Key Certifications and Quality Assurances ISO 9001 Certification: The most important assurance of quality is that the manufacturer is ISO 9001 certified. This confirms that the company's entire production process, from material selection to final inspection, is governed by a robust Quality Management System (QMS). Manufacturing Standards: The quality of an adjustable chuck is primarily defined by its ability to achieve a very low runout. This is verified through a manufacturer's internal testing and its compliance with established standards for concentricity, clamping force, and repeatability. Safety Compliance: As a workholding device, the chuck's design must comply with safety standards related to its clamping mechanism to ensure it securely holds the workpiece under all operating conditions.

Product Description

An accuracy adjustable chuck is a specialized type of lathe chuck designed for high-precision machining applications. The "80mm TO 315MM " refers to the chuck's diameter, which is a common size for medium to large lathes. While a standard self-centering chuck provides good concentricity, an adjustable chuck goes a step further by allowing the operator to fine-tune the workpiece's position for near-perfect runout.

Key Features and Design

-

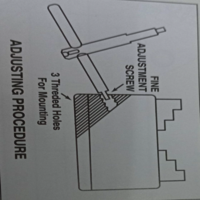

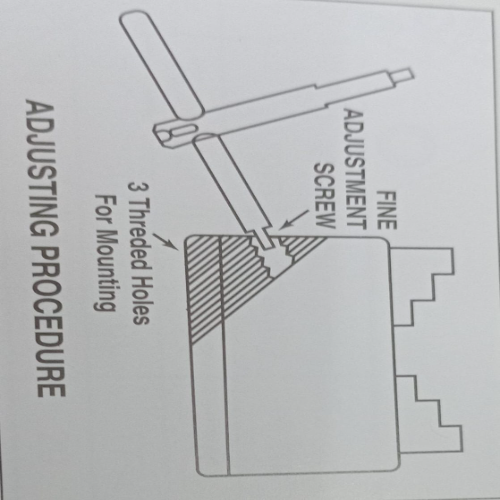

Adjustable Runout: The primary feature is a set of radial adjusting screws located on the chuck's body. After the workpiece is clamped, a dial indicator is used to measure runout. The adjusting screws are then manipulated to shift the entire chuck assembly radially, allowing the operator to achieve near-zero runout, typically within 0.005mm.

-

High Repeatability: This type of chuck is engineered for jobs that require repetitive, high-tolerance setups. Once the runout is adjusted for a specific part, subsequent parts of the same size can be clamped with very low runout, saving significant setup time.

-

Construction: Adjustable chucks are built with a robust, often semi-steel or cast iron body, and feature hardened and ground jaws and scroll threads for long-term durability and accuracy. They can be found in both 3-jaw and 6-jaw configurations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email