- Home Page

- Company Profile

-

Our Products

- Power Chuck And Chuck Spares

- Industrial Gears

- GNMT Precision Vices

- Lathe Machine

- Lead Screws

- Revolving Center

- CNC Lathe Turret Boring Sleeve

- Drill Machines

- Rotary Cylinders

- Universal Dividing Heads

- Angle Plates

- Sliding Tables

- Rotary Table

- Boring Head Set

- Industrial Grinder

- Milling Machine

- Operating Handles

- Back Plates / Mounting Flanges

- Tapping Machine

- Surface Grinding Machine

- Band Saw Machine

- Face Plate Jaws

- Milling Reduction Sockets

- Jaws Boring Rings

- Bonet Bonmac Independent Dog Chuck

- Magnet Chuck

- Drill Chuck

- KKF Independent Dog Chuck

- Seco Independent Dog Chuck

- Soft Jaws CNC Chucks

- Deluxe Independent Dog Chuck

- Hard Jaws CNC Chucks

- Collet Power Chucks

- True Chuck

- ACCURACY ADJUSTABLE CHUCK

- CHUCK Spare Parts

- COOKER LATHE CHUCKS

- ACCURACY ADJUSTABLE CHUCK

- SECO TRUE CHUCK

- TURNO TRUE CHUCK

- DUST PROOF SELF CENTRING CHUCK

- MTM TRUE CHUCK

- PNEUMATIC CHUCK

- DELUXE SELF CENTERING CHUCK

- GAMET SELF CENTERING CHUCK

- MIEKA TRUE CHUCK

- MASTER GRIPPING CHUCK

- MASTER GRIPPING CHUCK ( TURNO)

- Master Gripping Chuck ( Seco)

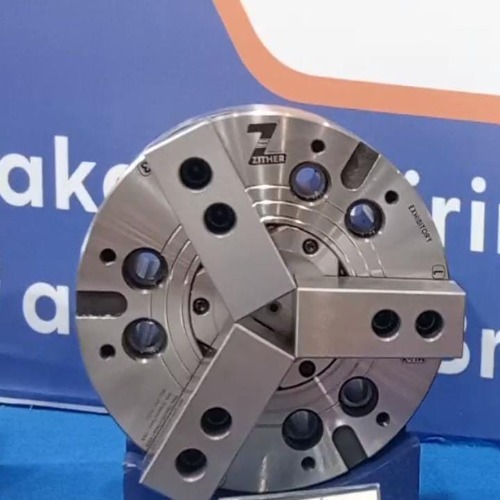

- ZITHER TRUE CHUCK

- Six Jaws True Chucks

- Collet Chuck

- Distributor

- Contact Us

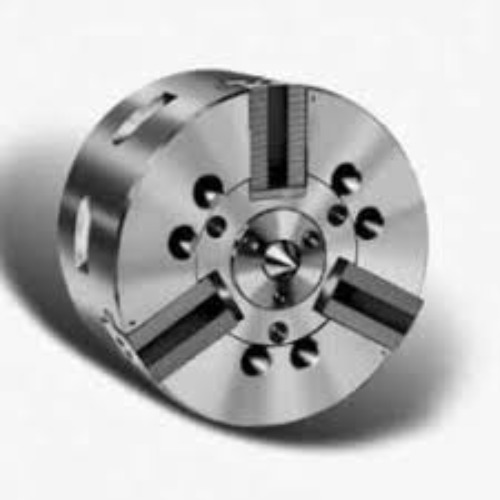

seco POWER CHUCK

25000.00 INR/Piece

Product Details:

- Diameter 203.2 Millimeter (mm)

- Phase Manual

- Shape Industrial Grey / Black with coated finish

- Torque 300 N-m

- Product Type 3 -4 Jaw Hydraulic POWER

- General Use Automatic clamping of round and irregular workpieces on CNC turning centers

- Material Hardened Metals

- Click to view more

X

seco POWER CHUCK Price And Quantity

- 2 Piece

- 25000.00 INR/Piece

seco POWER CHUCK Product Specifications

- Chrome Plating

- Yes

- 300 N-m

- No

- 0.02 Millimeter (mm)

- 100 Pcs/min

- Industrial Grey / Black with coated finish

- 22 Kilograms (kg)

- Manual

- 3D

- PLC Control

- 3 -4 Jaw Hydraulic POWER

- 220 Volt (v)

- No

- In-process quality control with runout testing

- 1

- Automatic clamping of round and irregular workpieces on CNC turning centers

- Industrial Grey / Black with coated finish

- 203.2 Millimeter (mm)

- Simple Control, Stable Operation, High Performance, ECO Friendly

- Hardened Metals

- 403 Millimeter (mm)

seco POWER CHUCK Trade Information

- TKD

- Cash Against Delivery (CAD)

- 10 Piece Per Month

- 5 Days

- No

- Contact us for information regarding our sample policy

- CORRUGATED CORASIS

- All India

- TURNO is a leading manufacturer of lathe chucks and machine accessories in India, and their commitment to quality is a central part of their brand identity. ISO Certified Company: Turno Chucks is an ISO certified company. This indicates that their manufacturing facility and processes adhere to the internationally recognized standards for a Quality Management System (QMS). The ISO certification confirms that the company has a structured approach to ensure consistent product quality, meet customer expectations, and maintain a framework for continuous improvement. Quality Assurance & Testing: Product descriptions for Turno's power chucks and other chucks consistently emphasize a focus on rigorous quality control. Key points include: Material Composition: The chuck bodies are manufactured from high-tensile alloy steel, case-hardened, and precision-ground to ensure durability and accurate fitting. High Hardness: The jaws and other key components are made from alloy steel that is hardened and ground, often to a hardness of 55-60 HRC, for excellent wear resistance. Dimensional Accuracy: The products are designed for precise accuracy, with some models promising runout of less than 0.05 mm.

Product Description

The SECO Power Chuck, manufactured by State Engineering Corporation, is a high-performance workholding solution designed for modern CNC lathes and turning centers. With a history spanning over six decades, SECO has become a trusted name in the industry for providing a wide range of workholding solutions, and their power chucks are a testament to their focus on innovation and quality.

SECO power chucks are engineered for high-speed operation, strong gripping, and constant accuracy, making them ideal for high-volume production and universal machining. They utilize a wedge hook design with a through-hole (open center) that allows for bar feeding and continuous machining operations. This design provides powerful clamping and a self-locking feature, which prevents the chuck from losing its gripping power even under significant cutting loads.

Key Features and Advantages:

-

High-Speed Operation: SECO power chucks are balanced for high rotational speeds, with some models capable of reaching up to 6000 RPM, making them suitable for modern, high-speed CNC machines.

-

Strong Gripping Force: The wedge hook design generates a high gripping force, with some models rated at over 3000 Kgf, ensuring a secure and stable hold on the workpiece to prevent slippage during heavy cuts.

-

Constant Accuracy & High Endurance: All sliding surfaces are hardened and precision ground for accurate running and long service life. The use of high-grade alloy steel and a robust design ensures the chuck maintains its accuracy and endurance over many years of use.

-

Versatile Configurations: SECO offers a comprehensive range of power chucks, available in 2, 3, and 4-jaw configurations, as well as various sizes (e.g., 170mm, 200mm, 250mm, 315mm) to fit a wide variety of machine spindles.

-

Open Center Design: The open center (through-hole) feature is crucial for bar work, allowing long bars to pass through the chuck and spindle, which is essential for efficient production.

-

CE Marked and ISO Certified: SECO is an ISO 9001-2008 certified company (which has since been updated to ISO 9001:2015) and its products are CE marked. This demonstrates their commitment to both international quality management standards and safety compliance for the European market.

The SECO Power Chuck is a robust and reliable workholding solution for machinists who need a high-performance chuck that delivers speed, accuracy, and strong gripping force for demanding CNC applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email