- Home Page

- Company Profile

-

Our Products

- Power Chuck And Chuck Spares

- Industrial Gears

- GNMT Precision Vices

- Lathe Machine

- Lead Screws

- Revolving Center

- CNC Lathe Turret Boring Sleeve

- Drill Machines

- Rotary Cylinders

- Universal Dividing Heads

- Angle Plates

- Sliding Tables

- Rotary Table

- Boring Head Set

- Industrial Grinder

- Milling Machine

- Operating Handles

- Back Plates / Mounting Flanges

- Tapping Machine

- Surface Grinding Machine

- Band Saw Machine

- Face Plate Jaws

- Milling Reduction Sockets

- Jaws Boring Rings

- Bonet Bonmac Independent Dog Chuck

- Magnet Chuck

- Drill Chuck

- KKF Independent Dog Chuck

- Seco Independent Dog Chuck

- Soft Jaws CNC Chucks

- Deluxe Independent Dog Chuck

- Hard Jaws CNC Chucks

- Collet Power Chucks

- True Chuck

- ACCURACY ADJUSTABLE CHUCK

- CHUCK Spare Parts

- COOKER LATHE CHUCKS

- ACCURACY ADJUSTABLE CHUCK

- SECO TRUE CHUCK

- TURNO TRUE CHUCK

- DUST PROOF SELF CENTRING CHUCK

- MTM TRUE CHUCK

- PNEUMATIC CHUCK

- DELUXE SELF CENTERING CHUCK

- GAMET SELF CENTERING CHUCK

- MIEKA TRUE CHUCK

- MASTER GRIPPING CHUCK

- MASTER GRIPPING CHUCK ( TURNO)

- Master Gripping Chuck ( Seco)

- ZITHER TRUE CHUCK

- Six Jaws True Chucks

- Collet Chuck

- Distributor

- Contact Us

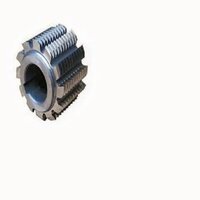

HOBBING CUTTERS

4000.00 INR/Piece

Product Details:

- Usage Machine Tools, CNC, Automotive, Heavy Machinery, Power Transmission

- Gear Type Spur Gears

- Material Stainless Steel

- Processing Type Precision Casting

- Size 50 2000 mm

- Height 5 Inch (in)

- Gear Tooth Profile Helical Gear

- Click to view more

X

HOBBING CUTTERS Price And Quantity

- 2 Piece

- 4000.00 INR/Piece

HOBBING CUTTERS Product Specifications

- 5 Inch (in)

- Industrial Gear / Transmission Gear / Reduction Gear

- 100 N-m

- 10 Kilograms (kg)

- 10 Inch (in)

- Precision Casting

- 10 RPM

- Industrial Grey / Black Oxide / Customized

- Machine Tools, CNC, Automotive, Heavy Machinery, Power Transmission

- 50 2000 mm

- Helical Gear

- 5 Inch (in)

- 0.10

- 94%

- Left Hand / Right Hand / Double Helical

- 220 Volt (v)

- Stainless Steel

- 250 RPM

- Helical

- Spur Gears

HOBBING CUTTERS Trade Information

- TKD

- Cash Against Delivery (CAD)

- 15 Piece Per Month

- 6 Days

- Contact us for information regarding our sample policy

- CORRUGATED CORASIS

- Middle East

- All India

- Hobbing cutters, as specialized precision cutting tools, do not have specific product certifications. Instead, their quality and performance are guaranteed by the manufacturer's overall quality management system and their adherence to strict industry standards. Key Certifications and Quality Assurances ISO 9001 Certification: A reputable hobbing cutter manufacturer will be ISO 9001 certified. This is the most crucial certification as it ensures that the company's production processes are consistently managed to provide high-quality products. Dimensional and Accuracy Standards: The performance of a hob is defined by its compliance with international standards that govern its dimensions, tooth profile, and accuracy. Common standards include those from the ISO (e.g., ISO 54) and AGMA (e.g., AGMA 1012). Material Certification: The quality of a hob is also based on the material it is made from, such as high-speed steel (HSS) or carbide. Manufacturers will often provide a material test report to certify the material's composition and a report on the heat treatment process to ensure the required hardness and wear resistance.

Product Description

Our Gear Hob Cutter for spur and helical gears is manufactured in machine relieved and ground relieved profiles. Gear hob cutter is available with bore and keyway or with end drive slot in single start as well as multi start pitches in accuracies class "A" 'B' and class 'C' with special features like topping, semi-topping, protuberance, pre-grinding, pre-shaving etc. manufactured to DIN, BS and IS specifications. We are counted among the predominant involute gear cutter suppliers and gear cutter manufacturers, based in India.Key Features and Design

-

Helical Profile: The hob has multiple cutting teeth arranged helically around its circumference. As the hob and the gear blank rotate in a synchronized motion, the hob's teeth gradually "cut" the profile of the gear teeth into the blank.

-

Material: Hobbing cutters are made from high-speed steel (HSS) or, for more demanding applications, from tungsten carbide. These materials provide the necessary hardness and toughness to cut through various metals.

-

Precision and Accuracy: The profile of a hobbing cutter's teeth is designed to be highly precise to ensure that the generated gear teeth are accurate and conform to specific standards, such as those from ISO or AGMA.

-

Types: Hobbing cutters come in various types depending on the application:

-

Topping Hobs: Cut the teeth and the outside diameter of the gear simultaneously.

-

Semi-Topping Hobs: Cut the teeth and a portion of the outside diameter.

-

Pre-grinding Hobs: Cut the rough profile of the gear teeth, which is then finished by grinding.

-

-

Benefits: Hobbing offers several advantages, including high production rates, consistent quality, and the ability to produce a wide range of gear types with a single machine.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email