SS Milling Reduction Sockets

SS Milling Reduction Sockets Specification

- Phase

- NO

- Diameter

- 70 Millimeter (mm)

- Shape

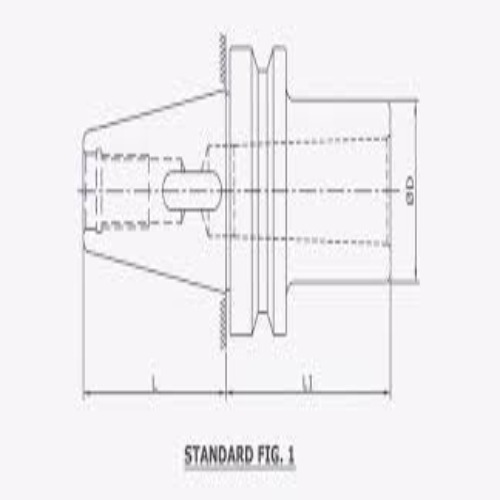

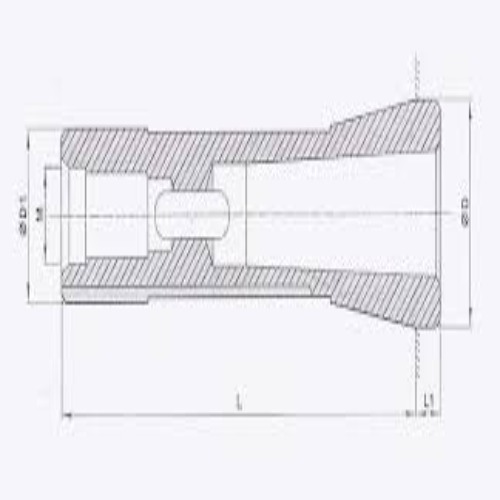

- Cylindrical Tapered with Precision Internal Bore

- Product Type

- Machine Tool Accessory Reduction Socket / Tool Holder Adapter

- General Use

- Industrial

- Material

- Other

- Type

- Milling

- Capacity

- 30 Pcs/min

- Weight (kg)

- 3 Kilograms (kg)

- Computerized

- No

- Automatic

- No

- Touch Screen

- Yes

- Control System

- Other

- Surface Treatment

- Polishing

- QC System

- The Milling Reduction Socket is manufactured under a robust certified Quality Management System, ensuring consistent product quality and dimensional accuracy. Each socket undergoes a strict multi-stage inspection process, including: Raw Material Testing To ensure hardness, grain structure, and chemical composition Dimensional Accuracy Check Using high-precision instruments like CMMs, micrometers, and gauges to ensure taper accuracy (e.g., BT, ISO, MT standards) Concentricity & Runout Inspection Ensuring runout tolerance typically within 5 microns Hardness Testing To confirm that the heat-treated body meets the required HRC (usually 56 60 HRC) Surface Finish & Coating Check Verifying anti-rust treatment and surface smoothness Final QC Report Each batch is accompanied by an internal inspection certificate or QA stamp

- Tolerance

- 2 Millimeter (mm)

- Drawing

- 3D

- Dimension (L*W*H)

- 70 Millimeter (mm)

- Feature

- ECO Friendly

- Color

- Silver

SS Milling Reduction Sockets Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- TKD

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 2 Days

- Sample Available

- No

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- CARRUGATED CORASIS

- Main Export Market(s)

- Middle East

- Main Domestic Market

- All India

- Certifications

- The Milling Reduction Socket is manufactured in compliance with international machining standards to ensure precision, durability, and compatibility with various tool holding systems. Each socket is engineered using high-grade alloy steel and hardened to maintain structural integrity under high-speed and heavy-load milling operations. These sockets typically conform to DIN, ISO, or JIS standards depending on the taper type (BT, ISO, MT, etc.). Most manufacturers, including Turnmax, produce these components under an certified quality management system, which guarantees consistent product quality and rigorous inspection processes. The reduction socket may also be accompanied by a manufacturer s test certificate or dimensional accuracy report, ensuring compliance with engineering tolerances and industrial safety standards.

About SS Milling Reduction Sockets

Introducing the SS Milling Reduction Sockets, a top-of-the-line industrial product made of high-quality stainless steel. These sockets are designed to provide precision and accuracy in milling machines, making them ideal for various industrial applications. The surface treatment of these sockets includes polishing, which not only makes them visually appealing but also enhances their durability. The silver color of these sockets complements their sleek design, making them a perfect addition to any industrial setup. One of the most notable features of the SS Milling Reduction Sockets is their eco-friendliness. They are made of stainless steel, which is a recyclable material, ensuring that they are environmentally sustainable. These sockets are suitable for a wide range of milling applications, making them a versatile tool for any industrial project. As an exporter, manufacturer, supplier, trader, and wholesaler, we take pride in offering top-notch products that meet the highest quality standards. The SS Milling Reduction Sockets are no exception, and we guarantee their reliability and durability.

FAQs of SS Milling Reduction Sockets:

Q: What is the material used to make the SS Milling Reduction Sockets?

A: The SS Milling Reduction Sockets are made of high-quality stainless steel, making them durable and reliable.Q: What is the surface treatment used on these sockets?

A: The surface treatment used on the SS Milling Reduction Sockets is polishing, which enhances their durability and visual appeal.Q: Are these sockets eco-friendly?

A: Yes, these sockets are eco-friendly as they are made of stainless steel, which is a recyclable material.Q: What is the general use of these sockets?

A: The SS Milling Reduction Sockets are designed for industrial use and are suitable for a wide range of milling applications.Q: What makes these sockets stand out from other industrial products?

A: The SS Milling Reduction Sockets are made of high-quality stainless steel, are eco-friendly, and have a polished surface treatment, making them durable, reliable, visually appealing, and suitable for various industrial applications.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email