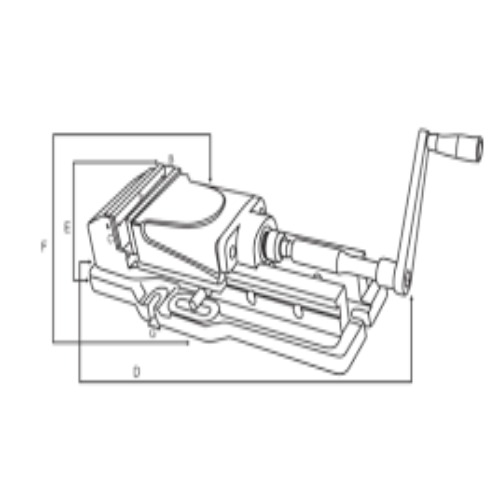

Hydraulic vice

Hydraulic vice Specification

- Application

- Secure clamping of workpieces during milling, drilling, grinding, and precision machining operations.

- Power Source

- Hydraulic (manual pump or machine-integrated hydraulic system).

- Tool Type

- Workholding Tool Hydraulic Machine Vice

- Noise Level

- 50 db

- Cutting Speed

- 150 mm/m

- Spindle Speed

- 150 mm/m

- Product Type

- Hydraulic Machine Vice

- Material

- High-grade Cast Iron body with Hardened & Ground Steel Jaws

- Computerized

- No

- Automatic Grade

- Manual

- Control System

- PLC Control

- Drive Type

- Manual

- Voltage

- 0 Volt (v)

- Weight (kg)

- 40 Kilograms (kg)

- Dimension (L*W*H)

- 890 Millimeter (mm)

- Capacity

- 180 Pcs/min

- Feature

- Simple Control, High Performance, Low Noise, ECO Friendly, Lower Energy Consumption

- Color

- Blue

- Warranty

- 1

Hydraulic vice Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- TKD

- Payment Terms

- Cash Against Delivery (CAD)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 15 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- CORRUGATED CORASIS

- Main Export Market(s)

- Middle East

- Main Domestic Market

- All India

- Certifications

- CE Marking: For any hydraulic vice sold in the European Economic Area (EEA), CE marking is a mandatory certification. It indicates that the product has undergone a conformity assessment and meets all relevant EU safety, health, and environmental protection requirements, particularly those outlined in the Machinery Directive (2006/42/EC). ISO 9001: This is not a product-specific certification but rather a standard for the manufacturer's Quality Management System (QMS). A manufacturer with ISO 9001 certification demonstrates that it has a consistent, well-documented process for producing high-quality products. This assures customers that the hydraulic vice is made with a commitment to quality and continuous improvement. Safety Standards (e.g., EN ISO 12100): Hydraulic vices, as a type of machinery, must adhere to general safety principles for machine design. Standards like EN ISO 12100 provide guidelines for risk assessment and risk reduction to ensure the machine is safe for the operator. Manufacturers who follow these standards will incorporate safety features to prevent accidents related to high pressure, clamping, and moving parts. Fluid Power Certifications: While not directly a product certification, a manufacturer's expertise in fluid power is often demonstrated through certifications like those from the International Fluid Power Society (IFPS). A company that employs certified hydraulic specialists and technicians is more likely to produce a safe and reliable hydraulic vice.

About Hydraulic vice

A hydraulic vice works by converting a small, mechanical force into a much larger hydraulic force. A small piston, typically actuated by a hand crank or a foot pump, pushes hydraulic fluid into a cylinder connected to the movable jaw. The fluid pressure then exerts a massive force on a larger piston within the cylinder, which drives the movable jaw to clamp the workpiece. This force multiplication allows for exceptionally high clamping pressures with minimal effort from the operator.

Key Features and Advantages

-

Powerful and Consistent Clamping Force: Hydraulic vices are known for their ability to deliver a massive, uniform clamping force, often reaching several tons. This eliminates the risk of workpiece slippage, even during heavy-duty cutting, and ensures repeatable accuracy for every part.

-

Increased Efficiency and Reduced Fatigue: The clamping and unclamping process is quick and requires very little physical effort, which significantly reduces operator fatigue and streamlines workflows, especially in high-volume production environments.

-

Enhanced Precision: By providing a consistent clamping pressure, hydraulic vices prevent the workpiece from lifting or shifting, which is critical for maintaining precision and achieving tight tolerances.

-

Versatility: Many hydraulic vices come with adjustable pressure settings, allowing operators to secure a wide range of materials, from soft plastics to hard metals, without causing damage.

-

Ideal for Automation: Due to their precise and repeatable clamping, hydraulic vices can be easily integrated into automated systems for CNC machining and robotics, further increasing productivity

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in GNMT Precision Vices Category

MILLING VICE

Price 9500.0 INR / Piece

Minimum Order Quantity : 2 Pieces

Feature : High Performance, Low Noise, Lower Energy Consumption, High Efficiency

Automatic Grade : Manual

Weight (kg) : 15 Kilograms (kg)

Product Type : Milling Vice

PIN TYPE GRINDER VICE

Price 6500.0 INR / Piece

Minimum Order Quantity : 5 Pieces

Feature : Simple Control, High Performance, High Efficiency, Stable Performance

Automatic Grade : Manual

Weight (kg) : 7 Kilograms (kg)

Product Type : Pin Type Grinding Vice

Bench Vice

Price 12500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Feature : Simple Control, High Performance, Lower Energy Consumption, High Efficiency

Automatic Grade : Manual

Weight (kg) : 25 Kilograms (kg)

Product Type : HeavyDuty Bench Vice

SCREW TYPE GRINDING VICE

Price 6000.0 INR / Piece

Minimum Order Quantity : 5 Pieces

Feature : High Efficiency, Simple Control, High Performance

Automatic Grade : Manual

Weight (kg) : 9 Kilograms (kg)

Product Type : Screw Type Precision Grinding Vice