PIN TYPE GRINDER VICE

Product Details:

- Tool Type Manual Grinding Vice for precision toolroom operations

- Power Source Not Required (Manual)

- Noise Level 0 db

- Application Surface Grinding, EDM, Toolroom Inspection, Jig Boring

- Product Type Pin Type Grinding Vice

- Click to View more

PIN TYPE GRINDER VICE Price And Quantity

- 6500.0 INR/Piece

- 5 Piece

PIN TYPE GRINDER VICE Product Specifications

- Simple Control, High Performance, High Efficiency, Stable Performance

- Surface Grinding, EDM, Toolroom Inspection, Jig Boring

- 7 Kilograms (kg)

- Manual

- 1

- No

- Pin Type Grinding Vice

- Manual Grinding Vice for precision toolroom operations

- Human Machine Interface

- 0 db

- Not Required (Manual)

- Silver

- Manual

- 0 Volt (v)

- 310 Millimeter (mm)

- Hardened Tool Steel

- 15 Kg

PIN TYPE GRINDER VICE Trade Information

- TKD

- Cash Against Delivery (CAD)

- 10 Piece Per Month

- 7 Days

- Yes

- Contact us for information regarding our sample policy

- CORRUGATED CORASIS

- Middle East

- All India

- The Pin Type Grinding Vice is manufactured under strict quality control as per international standards. It is certified under the ISO 9001:2015 quality management system to ensure consistent dimensional accuracy, hardness, and performance. Each vice is supplied with a Material Test Certificate (MTC) confirming steel grade, hardness (HRC 55 60), and precision grinding. For exports, optional CE Certification, Certificate of Origin (COO), and Third-Party Inspection Reports (SGS / TUV / DNV) can be provided upon request. The product also meets compliance under India s MSME / Registration for official domestic and international trade.

Product Description

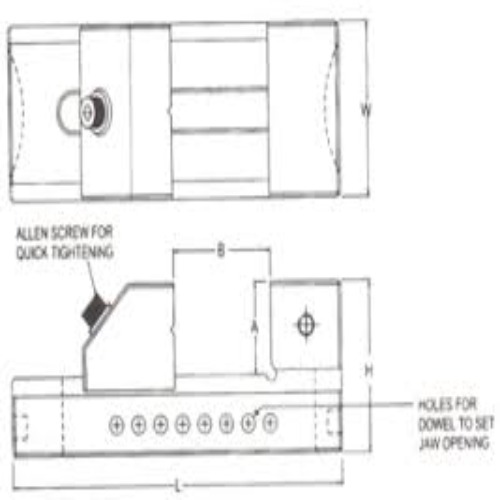

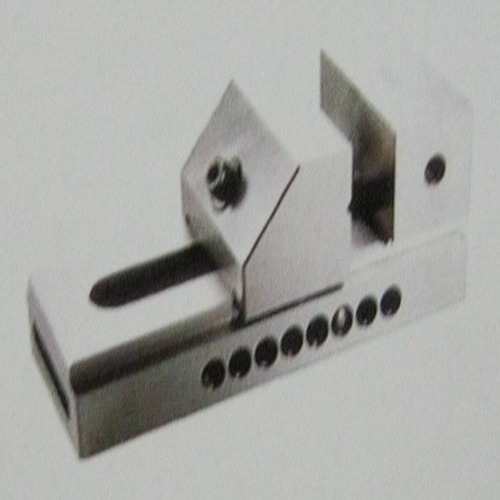

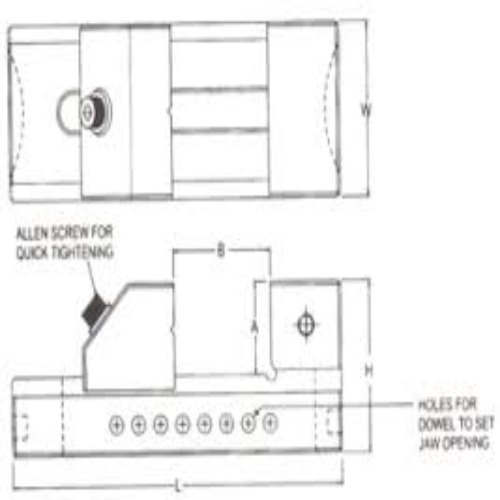

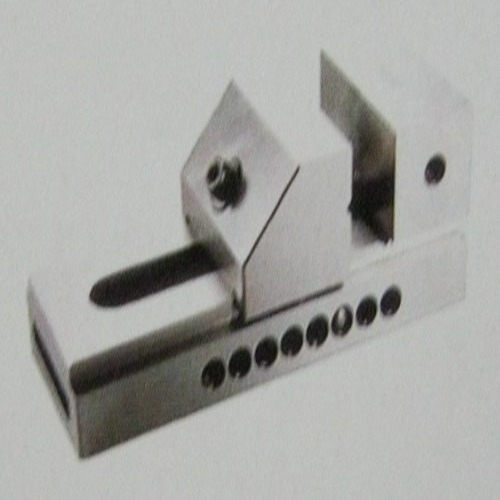

The Pin Type Grinding Vice is a precision-engineered tool designed for high-accuracy grinding, inspection, and light milling operations. Crafted from hardened alloy steel and ground to tight tolerances, this vice features removable pins or slip-in location pins that allow flexible and precise clamping of irregular or small workpieces. It is widely used in tool rooms, EDM machines, surface grinders, and inspection departments for holding jobs at precise angles or positions.

Its compact, low-profile body and corrosion-resistant finish make it ideal for repeatable accuracy and minimal deflection during fine machining or measurement work.

"Sample Line: Pin Type Grinding Vice precision workholding solution for toolrooms, EDMs, and surface grinding with exceptional repeatability and flexibility"

Q1. What is a Pin Type Grinding Vice used for?

It is used to hold small, thin, or irregular-shaped workpieces during grinding, EDM, inspection, or precision toolroom operations.

Q2. What is the difference between a pin type and regular grinding vice?

A pin type vice uses removable locating pins that adjust to the jobs size and shape, offering more flexibility than fixed jaw vices.

Q3. Is this vice suitable for CNC or EDM?

Yes. It is commonly used on EDM, surface grinding machines, and jig boring setups for holding delicate or precision components.

Q4. What is the material and hardness of the vice?

Made from hardened tool steel, heat-treated to HRC 5560, with fully ground surfaces.

Q5. What is the accuracy of this vice?

Parallelism and squareness are maintained within 0.005 mm, suitable for high-precision jobs.

Q6. Can the pins be replaced or repositioned?

Yes. The pins are removable and adjustable, allowing quick clamping for various job sizes and shapes.

Q7. Does it require power or is it manual?

It is manual no electricity or hydraulic system required.

Q8. What sizes are available?

Typically available in lengths of 75 mm, 100 mm, and 150 mm, with custom sizes available on request.

Q9. What is the weight and pack size?

Depends on model:

100 mm vice approx. 46 kg

Packed in protective box with oil wrap and foam

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+